TECHNICAL DATA SHEET

Product information

FAST SHIPPING AND SUPER PACKAGING! 25 METERS OF KME WICU CLIM 5/8" X 0.8 MM COPPER AIR CONDITIONING PIPE

Technical Features

-

Model

25 METERS OF COPPER PIPE FOR AIR CONDITIONING KME WICU CLIM 5/8” X 0.8 MM

-

Characteristics

Manufacturer: KME

Type: Wicu Clim

Outside diameter: 5/8"

Dimensions: 15.87 x 0.8 mm

Roll length: 25 m

Coating thickness: 10 mm

Burst pressure: 28.28 MPa

Working pressure: 7.07 MPa

Water content: 0.151 (l/m)

Unit price per meter (Quantity 1 = 1 Meter)

General Features

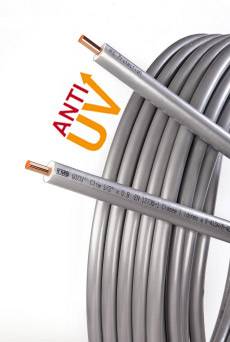

WICU® Clim

WICU® Clim represents the ideal solution for the creation of air conditioning systems.

WICU®Clim is the result of the experience and synergies between KME Group companies. It complies with the technical specifications required by recent European regulations regarding air conditioning and the transport of new refrigerants (R410A, R407C, etc.).

This copper tube is manufactured according to the EN 12735-1 standard and is pre-insulated with closed-cell polyethylene foam of regular and uniformly distributed size (EN 14114). It is supplied in rolls. The diameter of the copper tube, as required by the EN 12735-1 standard, is expressed in inches.

The insulating sheath is produced in full compliance with European Regulation EEC/EU 2037/2000, which mandates the use of expanded insulating sheaths free of CFCs and HCFCs, gases harmful to health and the environment. The sheath's thickness is also sized to meet the diverse needs of this application sector.

Given the specific nature of the field of use, special attention is paid to the external protective polyethylene film aimed at preventing the formation of condensation on the external wall of the product.

WICU® Clim is also characterised by particularly low eccentricity values, a very important feature for the flaring operation.

Internal surface

The internal surface of the copper tube is shiny, clean, and dry—essential characteristics of a product commonly found on the market for industrial use. This unique feature allows for an integrated system with the terminal components of the system. The exceptional internal cleanliness of WICU® Clim is ensured by sealing the ends of each roll with caps, directly during production.

External protection

Closed-cell expanded polyethylene coating with an average water vapor diffusion resistance factor “μ” equal to 10000. The insulating sheath is produced in full compliance with European Regulation EEC/EU 2037/2000 which requires the use of expanded insulating sheaths without the use of CFCs and HCFCs, gases harmful to health and the environment, and has a class 1 fire behavior according to Ministerial Decree 26/06/84.

The outer polyethylene film contains a darker pigment than traditional white to counteract the crystallization process of PE. Furthermore, conventional UV-protective additives counteract the flame retardant required by the product. To avoid this, the WICU® Clim sheath contains an environmentally friendly, halogen-free flame retardant that does not counteract the UV-protective effect.

Tests conducted according to ASTM G-155 (accelerated aging) demonstrate that WICU® Clim is suitable for areas with strong annual solar radiation. At the end of the exposure test, the sample showed no signs of degradation.

Areas of use:

Conditioning

Refrigerant gas transport

In compliance with and within the limits established by the regulations.

Characteristics of copper tube:

Produced according to EN 12735-1

Physical state: R220 (rolls)

Absolute roughness: e.= 0.0015 mm

Coefficient of linear thermal expansion: 0.0168 mm/m°C

Thermal conductivity: λ= 364 W/m°C (at 20°C)

Internal cleaning: according to EN 12735-1 (and ASTM B 280)

It does not soften at high temperatures

Absolute impermeability to gases

UV resistant

Coating features:

Closed-cell expanded polyethylene

Thermal conductivity: λ≤0.040 W/m°C

Average value of the water vapor diffusion resistance factor: "μ" = 10,000

Average coating density: 33 kg/m3

Free from ammonia residues

Excellent resistance to external chemical agents

Non-flammable class 1

CONTINUE SHOPPING

Recommended for you

- Choosing a selection results in a full page refresh.

!