TECHNICAL DATA SHEET

Product information

These units are used for both heating and cooling applications and domestic hot water tanks. They can be combined with fan coil units, underfloor heating systems, high-efficiency low-temperature radiators, domestic hot water tanks, and solar kits, all of which are field-powered. A wired controller is included with the unit. The backup heater, available as an accessory, can increase heating capacity in cold outdoor temperatures. The backup heater also serves as a backup in the event of a malfunction and as a freeze protection for outdoor water pipes during the winter.

Technical Features

-

Model

Beretta Hydronic Heat Pump Model HYDRO UNIT M 006 Single-Phase R-32 Air-Water Control Excluded

-

Energy Efficiency

Energy class in heating at 35°C: A+++

Energy class in heating at 55°C: A++

COP heating with water set to 35°C: 4.95

COP heating with water set at 45°C: 3.70

COP heating with water set to 55°C: 2.95

EER cooling with water set at 7°C: 3.00

EER cooling with water set at 18°C: 4.80 -

Performance

Heating

Useful power in heating with water set at 35°C: 6.35 kW

Useful power in heating with water set at 45° C: 6.30 kW

Useful power in heating with water set at 55°C: 6.00 kW

Power consumption with water set at 35°C: 1.28 kW

Power absorbed with water set at 45°C: 1.70 kW

Power consumption with water set at 55°C: 2.03 kW

Cooling

Useful power in cooling with water set at 7 °C: 7.00 kW

Useful power in cooling with water set at 18°C: 6.50 kW

Power consumption with water set at 7°C: 2.33 kW

Power absorbed with water set at 18°C: 1.35 kW -

Characteristics

Maximum operating pressure of the hydronic circuit: 3 bar

Maximum absorbed power: 0.043 kW

System expansion vessel: 8 litres -

Dimensions

Dimensions (LxHxD): 1295x792x429 mm

Empty weight: 98.0 kg

General Features

HYDRO UNIT

These units are used for both heating and cooling applications and domestic hot water tanks. They can be combined with fan coil units, underfloor heating systems, high-efficiency low-temperature radiators, domestic hot water tanks, and solar kits, all of which are field-powered. A wired controller is included with the unit. The backup heater, available as an accessory, can increase heating capacity in cold outdoor temperatures. The backup heater also serves as a backup in the event of a malfunction and as a freeze protection for outdoor water pipes during the winter.

Efficiency and sustainability

The HYDRO UNIT M series heat pumps use R32 refrigerant, a gas with a lower Global Warming Potential than traditional refrigerants. The design of a new sealed circuit for fluorinated gases, the use of R32, reduced load volumes, lower CO2 emissions, and increased energy efficiency are the features that differentiate the HYDRO UNIT M and increase its environmental sustainability.

Silence

The low noise level is guaranteed by the construction features used and can be further reduced thanks to the Silent Mode programming, available to the customer.

Antifreeze function

The HYDRO UNIT M heat pump is designed for outdoor installation and features an ANTIFREEZE function to protect the entire hydraulic circuit. This customer-programmable function activates automatically whenever the water temperature in the system drops below a preset value, ensuring the entire system is protected.

Better performance

The ten available models offer power from 4 kW to 16 kW, with a quick response to requests and reduced energy consumption that guarantee the energy class A+++ up to 35°C and A++ up to 55 °C.

HP KEYMARK Certification

The design meets the requirements of the voluntary European HP KEYMARK certification

Easy and flexible

Installing the HYDRO UNIT M is easy thanks to the hydronic kit that comes with the monoblock and contains all the essential components. The HYDRO UNIT M is flexible thanks to its ability to quickly respond to the real needs of the environments it serves.

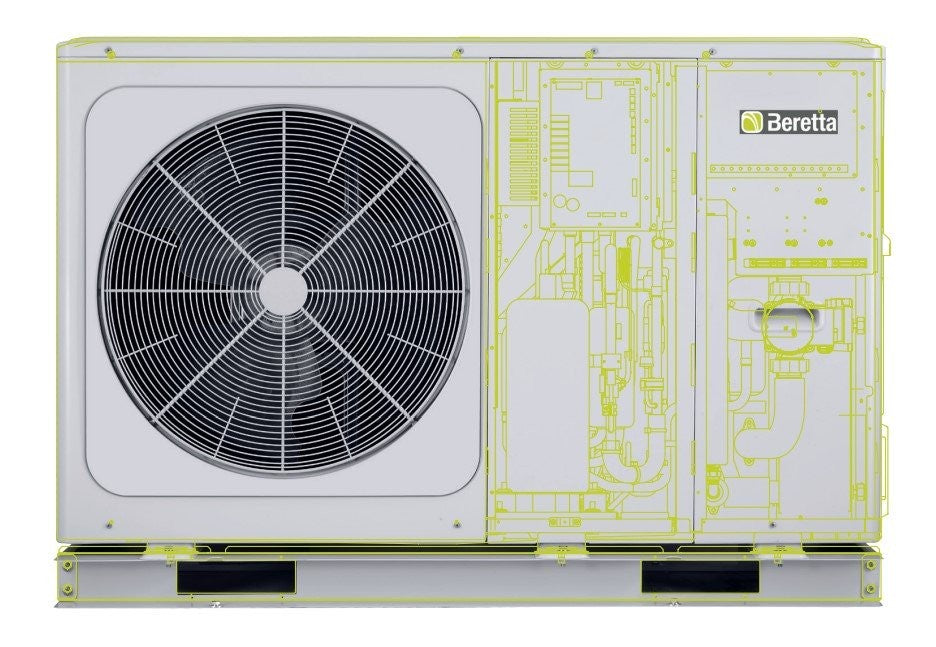

Inverter control board Maximizes power under critical load conditions and provides stability and efficiency at partial loads

Plate heat exchanger in AISI 316 steel: protected with closed cell anti-condensation insulation, it offers high heat exchange efficiency.

Control board Operating parameters constantly analyzes the ambient temperature and water temperature to activate the different components and meet the needs

Hydronic module Including low consumption circulator, expansion vessel, automatic vent valve and safety valve

Electronic expansion valve Optimizes the flow of refrigerant in every situation

Twin rotary compressor The Inverter System design that includes the DC twin rotary compressor, fan motor and pump ensures precise control of the motor speed for the right power needed to perfectly match the actual load and save energy.

Fan Special design of the blade and its edge that allows to optimize the flow surface improving efficiency and reducing fan noise

Heat exchange battery with extended surface and aluminium fins

CONTINUE SHOPPING

Recommended for you

- Choosing a selection results in a full page refresh.

!